正文:

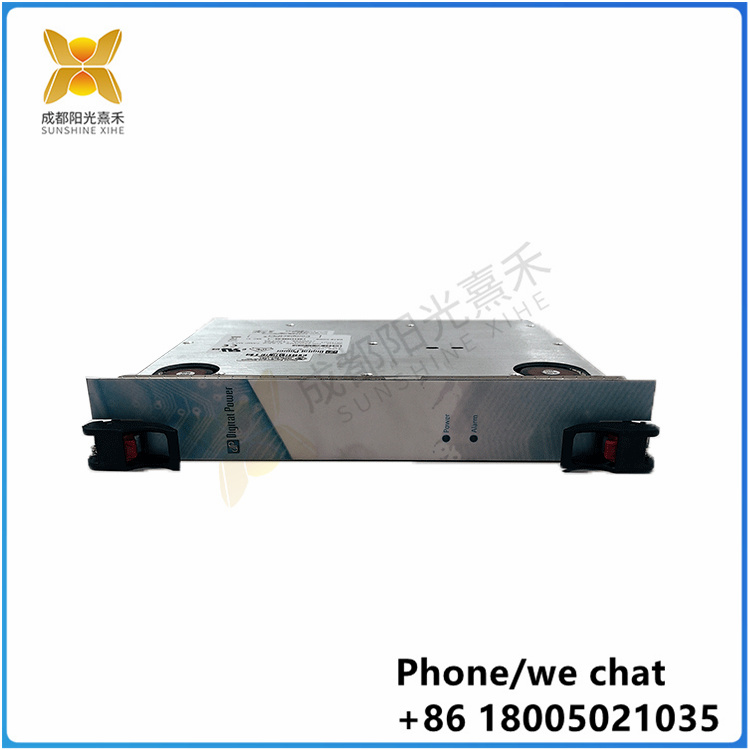

500BIO01 1MRB150005R1/J输入/输出模块。这款新一代模块以其卓越的性能和创新的设计,满足了现代工业自动化对于高效数据管理和设备控制的需求。

高性能数据处理: 500BIO01模块采用了先进的数据处理技术,提供了快速的输入/输出响应时间,确保了工业自动化系统中的实时控制和精确数据采集。

模块化设计: 该模块采用模块化设计理念,用户可以根据具体的应用需求灵活配置系统,实现快速部署和轻松扩展。

广泛的兼容性: 500BIO01模块与ABB其他自动化产品兼容,支持与多种PLC和控制单元的无缝集成,简化了工程实施的复杂性。

智能诊断功能: 集成的智能诊断工具可以实时监控模块的运行状态,快速识别并响应潜在的故障,减少系统停机时间,提高生产连续性。

网络安全加强: 在设计时充分考虑了工业环境的网络安全需求,500BIO01模块提供了多层安全防护措施,保护企业免受网络攻击和数据泄露的风险。

环境适应性: 模块设计用于适应各种工业环境条件,包括高温、高湿和多尘环境,确保了长期稳定运行。

易于维护: 控制器设计考虑了维护的便捷性,简化了故障诊断和维修流程,降低了企业的运营成本

这种模块可能的工作方式:

实时监控:智能诊断系统通过集成的传感器和实时数据采集系统,持续监测模块的运行状态,包括但不限于电压、电流、温度和信号质量等参数。

阈值检查:系统会设定各种运行参数的正常工作范围(阈值)。一旦监测到的参数超出这些范围,系统会立即发出警告,提示可能的异常情况。

故障预测:利用历史数据和机器学习算法,智能诊断系统能够预测潜在的故障模式,如部件磨损或性能下降,并在问题发生前提醒用户。

日志记录与分析:系统会记录操作日志和事件日志,用于事后分析和故障追踪,帮助技术人员了解问题发生的上下文和根本原因。

自适应调整:在一些高级系统中,智能诊断不仅能识别问题,还能自动调整模块的运行参数,以避免故障或优化性能。

用户界面通知:智能诊断系统通过用户界面提供实时反馈,包括状态指示灯、显示屏信息或通过软件界面的视觉和听觉提示。

远程诊断:在支持远程访问的系统中,智能诊断功能可以允许技术人员远程登录系统,进行问题的诊断和解决。

维护建议:系统可以根据诊断结果提供维护建议,包括需要更换的部件、推荐的维护周期或特定的操作步骤。

集成到更广泛的系统中:智能诊断功能可以集成到更广泛的工业物联网(IIoT)或智能制造系统中,与其他智能设备和系统协同工作。

安全特性:确保智能诊断系统本身的安全性,防止未授权访问和数据泄露,保护系统免受网络攻击。

500BIO01 1MRB150005R1/J

Title: ABB 500BIO01 Revolutionizes industrial input/output modules to improve the flexibility and efficiency of intelligent manufacturing

Subtitle: The 500BIO01 module, with its innovative design and high performance features, brings new connectivity solutions to industrial automation

Body text:

ABB, the global leader in industrial automation technology, today announced the launch of its newly developed 500BIO01 1MRB150005R1/J input/output module. This new generation module, with its superior performance and innovative design, meets the needs of modern industrial automation for efficient data management and equipment control.

High performance data processing: The 500BIO01 module uses advanced data processing technology to provide fast input/output response times, ensuring real-time control and accurate data acquisition in industrial automation systems.

Modular design: The module adopts a modular design concept, and users can flexibly configure the system according to specific application requirements, achieving rapid deployment and easy expansion.

Broad compatibility: The 500BIO01 module is compatible with other ABB automation products and supports seamless integration with multiple PLCS and control units, simplifying the complexity of engineering implementation.

Intelligent diagnostic function: The integrated intelligent diagnostic tool can monitor the operating status of the module in real time, quickly identify and respond to potential faults, reduce system downtime and improve production continuity.

Cybersecurity Enhancement: Designed with the cybersecurity needs of industrial environments in mind, the 500BIO01 module provides multiple layers of security to protect organizations from the risks of cyber attacks and data breaches.

Environmental adaptability: The modules are designed to adapt to a variety of industrial environmental conditions, including high temperature, high humidity and dusty environments, ensuring long-term stable operation.

Easy maintenance: The controller design takes into account the convenience of maintenance, simplifies the fault diagnosis and maintenance process, and reduces the operating costs of the enterprise

How such a module might work:

Real-time monitoring: The intelligent diagnostic system continuously monitors the operating status of the module through integrated sensors and real-time data acquisition systems, including but not limited to parameters such as voltage, current, temperature and signal quality.

Threshold check: The system will set the normal operating range (threshold) of various operating parameters. Once the monitored parameters fall outside these ranges, the system immediately issues a warning indicating possible anomalies.

Failure prediction: Using historical data and machine learning algorithms, intelligent diagnostic systems are able to predict potential failure patterns, such as component wear or degraded performance, and alert users before problems occur.

Log recording and analysis: The system records operation logs and event logs for later analysis and fault tracing to help technical personnel understand the context and root cause of problems.

Adaptive adjustment: In some advanced systems, intelligent diagnostics can not only identify problems, but also automatically adjust the operating parameters of the module to avoid failures or optimize performance.

User interface notifications: The intelligent diagnostic system provides real-time feedback through the user interface, including status indicators, display information, or visual and auditory cues through the software interface.

Remote diagnosis: In a system that supports remote access, the intelligent diagnosis function allows technicians to log in to the system remotely to diagnose and resolve problems.

Maintenance suggestions: Based on the diagnosis results, the system provides maintenance suggestions, including the parts to be replaced, recommended maintenance periods, and specific operations.

Integrated into a wider range of systems: Smart diagnostics capabilities can be integrated into a wider range of Industrial Internet of Things (IIoT) or smart manufacturing systems, working in concert with other smart devices and systems.

Security features: Ensure the security of the intelligent diagnostic system itself, prevent unauthorized access and data leakage, and protect the system from network attacks.

安全功能:支持TPM v2.0(可选),增强了数据保护,保障了工业控制系统的安全性。

安全功能:支持TPM v2.0(可选),增强了数据保护,保障了工业控制系统的安全性。

以下是智能诊断功能可能的工作机制和效益:

以下是智能诊断功能可能的工作机制和效益: