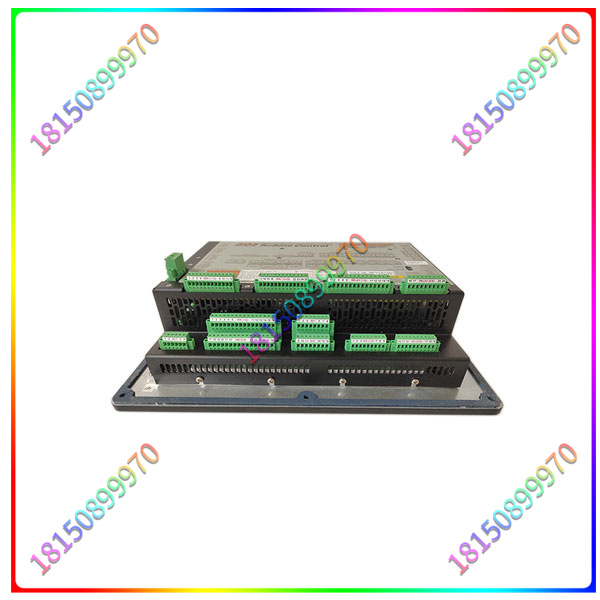

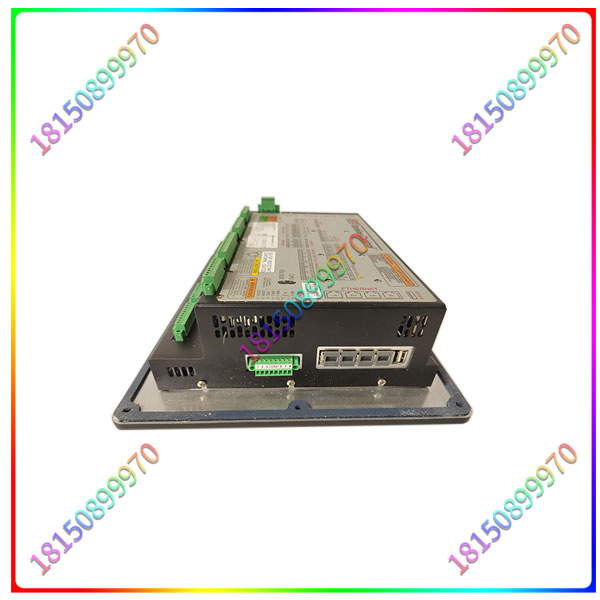

Woodward 505数字控制器(new) 8200-1300用于汽轮机

8200-1300,woodward 505是一种将可现场配置的汽轮机控制装置和操作员控制面板 (OCP) 合为一体的装置。505 的前面板上有一个综合的图形化操作员控制面板显示屏和键盘。该显示屏可用于对 505 配置,进行在线程序调整和操作汽轮机/系统。容易理解的说明可让操作员在汽轮机运行期间随时查看实际值和设定值。为符合 ATEX/IECEx 认证要求,505 数字控制器应安装在编码为 Ex nA 的机壳内,可提供低 IP54 的进入防护。安装人员应确保终安装位置处的高环境空气温度不超过 +70? 的额定温度。不应将 505 控制器安装在超过 IEC 60664-1 规定的“2 级污染”的区域中。在正常操作中,不应让人能在不使用工具的情况下接触到机壳内部。

件号选择

8200-1300 低压直流电(直流 18–32 V)标准合规性

8200-1301 交流/直流电(交流 88–132 V 或直流 90–150 V)

8200-1302 船用/ATEX 合规性低压直流电(直流 18–32 V)

8200-1300

8200-1300

该 505 控制器设计用于控制单执行机构或双(分程)执行机构汽轮机(抽汽式汽轮机需要使用 505XT 版本)。505 可现场编程,这样可以将一个单独的设计用于许多不同的控制应用场合,能够降低和缩短交付时间。它采用菜单驱动软件,以引导现场工程师根据具体的发电机或机械驱动应用对该控制器进行编程。可将 505 配置作为独立装置运行,也可配置为与电厂的分布式控制系统一起运行。8200-1300 505 控制器具有五个能够影响进入汽轮机的进汽流量需求的 PID 控制器:转速/负荷 PID 控制器、辅助 PID 控制器、辅助 2 PID 控制器,和串级 PID控制器。根据 505 的配置,这些 PID 互相有不同的交互。要完全了解 PID关系,请参照本章中稍后列出的各框图。可提供一个附加的 PID 作为分离的控制环路,该环路是可选的,可用于驱动可能需要的任何单环路辅助控制(如密封气、压盖密封件,或润滑油压力环路)的独立模拟输出信号(即不是驱动蒸汽阀)。当使用隔离 PID 控制时,建议为配置为“隔离 PID 要求”的模拟输出通道选择“启用回读故障”选项。如果检测到输出电路中的故障,这会触发 505 中的报警。默认情况下,不将模拟输出通道配置为在输出电路出现故障时产生报警。505 驱动一或两个汽轮机节流阀,用以一次控制一个汽轮机参数,且如果需要,可基于其他参数限制汽轮机运行。这一受到控制的参数通常为转速(或负荷),但是,可利用505 控制或限制:汽轮机入口压力或流量、排汽压力(背压)或流量、级压力、发电机的功率输出、电厂输入和/或输出水平、压缩机入口或排出压力或流量、机组/电厂频率、过程温度,或任何其他与汽轮机相关的过程参数。

8200-1300

Woodward 505 Digital Controller (new) 8200-1300 for steam turbines

The 8200-1300,woodward 505 is a combination of a field-configurable steam turbine control unit and an operator control panel (OCP). The 505 has a comprehensive graphical operator control panel display and keyboard on the front panel. The display can be used for on-line program adjustment and turbine/system operation on the 505 configuration. Easy-to-understand instructions allow the operator to view actual and set values at any time during turbine operation. To meet ATEX/IECEx certification requirements, the 505 digital controller shall be installed in a case coded Ex nA, providing low IP54 entry protection. The installation personnel shall ensure that the high ambient air temperature at the final installation location does not exceed the rated temperature of +70?. 505 controllers should not be installed in areas that exceed “Level 2 contamination” as defined by IEC 60664-1. During normal operation, people should not be able to access the inside of the housing without using tools.

Item number selection

8200-1300 Low voltage direct current (DC 18-32 V) standard compliance

8200-1301 AC/DC (88-132 V AC or 90-150 V DC)

8200-1302 Marine /ATEX Compliance Low voltage DC (DC 18-32 V)

8200-1300.

The 505 controller is designed to control single or double (split) actuator turbines (the 505XT version is required for extraction turbines). The 505 is field programmable, which allows a single design to be used for many different control applications, reducing and shortening delivery times. It uses menu-driven software to guide field engineers in programming the controller for a specific generator or mechanical drive application. The 505 configuration can be configured to operate as a stand-alone unit or in conjunction with the distributed control system of the power plant. The 8200-1300 505 controller has five PID controllers that can affect the demand for inlet flow into the turbine: the speed/load PID controller, the auxiliary PID controller, the auxiliary 2 PID controller, and the cascade PID controller. Depending on the 505 configuration, these Pids interact differently with each other. To fully understand the PID relationship, refer to the block diagrams listed later in this chapter. An additional PID is available as a separate control loop, which is optional and can be used to drive an independent analog output signal for any single-loop auxiliary control that may be required (i.e. not to drive the steam valve), such as sealing gas, gland seals, or oil pressure loops. When using isolated PID control, you are advised to select the Enable Read Back Fault option for the analog output channel that is configured as Isolated PID Requirement. If a fault in the output circuit is detected, this triggers an alarm in 505. By default, the analog output channel is not configured to generate an alarm when the output circuit fails. The 505 drives one or two turbine throttle valves to control one turbine parameter at a time and, if necessary, to restrict turbine operation based on other parameters. This controlled parameter is usually speed (or load), however, 505 can be used to control or limit: Turbine inlet pressure or flow, exhaust pressure (back pressure) or flow, stage pressure, generator power output, plant input and/or output level, compressor inlet or discharge pressure or flow, unit/plant frequency, process temperature, or any other process parameter associated with the turbine.

8200-1300

| WOODWARD | 2301E | WOODWARD | EGCP-3 8406-113 | WOODWARD | WOODWARD 5466-409 |

| WOODWARD | 8273-1011 | WOODWARD | 8440-1546 H 调速器 | WOODWARD | 8200-226 |

| WOODWARD | 9907-147 | WOODWARD | 2301A 9907-018 | WOODWARD | 9907-018 2301A |

| WOODWARD | 8200-1302 | Woodward | 8440-1706 | WOODWARD | 8273-140 2301D |

| WOODWARD | 5233-2089 | WOODWARD | SPM-D11 负荷分配器 | WOODWARD | SPM-D11 8440-1706B |

| WOODWARD | 8200-1300 | WOODWARD | EGCP-2 8406-121 电子控制EGCP | WOODWARD | 9907-205 |

| WOODWARD | 9907-164 | WOODWARD | EGCP-3 8406-113 | woodward | XU2-AC交流电压继电器 |

| WOODWARD | 9907-164 | WOODWARD | 8200-1300 | WOODWARD | 9907-1290 |

| WOODWARD | 9907-1290 |

There are no reviews yet.