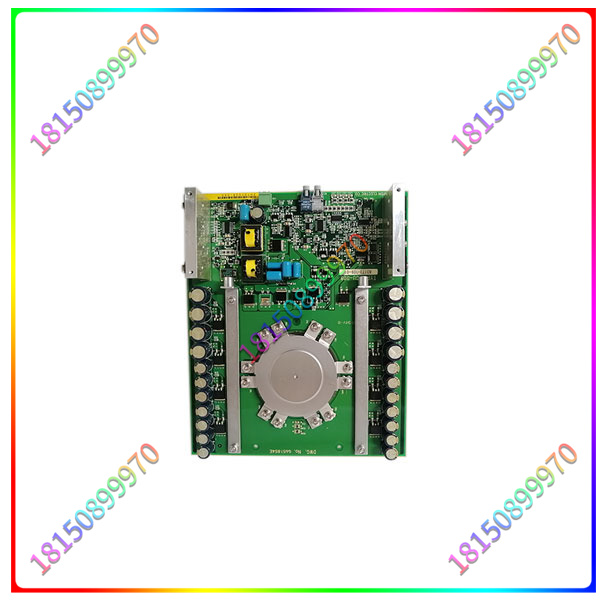

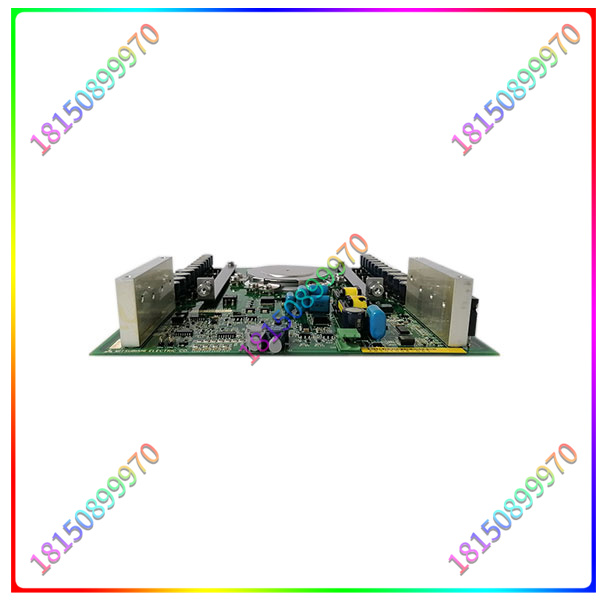

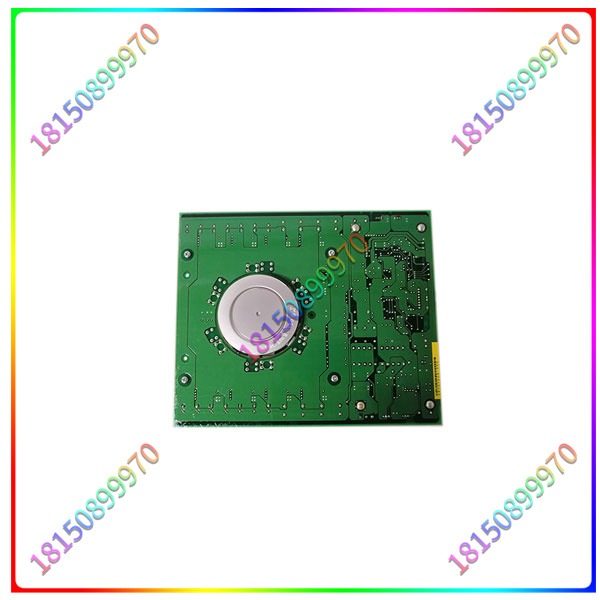

81001-450-53-R A-B高压变频器模块

I.中央处理单元(CPU)

中央处理单元(CPU)是PLC的控制中枢。它按照PLC系统程序赋予的功能接收并存储从编程器输入的用户程序和数据,检查电源、存储器、VO以及警戒定时器的状态,并能诊断用户程序中的语法错误:当PLC投入运行时,首先它以扫描的方式接收现场各输入装置的状态和数据,并分别存入IO映像区,然后从用户程序存储器中逐条读取用户程序,经过命令解释后,按指令的规定将逻辑或算术运算的结果送入Vo映像区或数据寄存器内。等所有的用户程序执行完毕之后,最后将1/O映像区的各输出状态或输出寄存器内的数据传送到相应的输出装置,如此循环运行,直到停止运行为止。为了进一步提高PLC的可靠性,近年来对大型PLC还采用双CPU构成冗余系统,或采用三CPU的表决式系统。这样,即使某个CPU出现故障,整个系统仍能正常运行。

81001-450-53-R

存储器

存放系统软件的存储器称为系统程序存储器。

(1) PLC常用的存储器类型。

1) RAM (Random Assess Memory)。这是-一种读/写存储器(随机存储器)其存取速度最快,由铿电池支持。

2) EPROM (Erasable Progranmable Read Only Memory)。这是一种可擦除的只读存储

器在断电情况下存储器内的所有内容保持不变(在紫外线连续照射下可擦除存储器内容)。

3) EPROM (Electrical Erasable Programmable Read Only Memory)。这是一种电可擦除的只读存储器。使用编程器就能很容易地对其所存储的内容进行修改。

(2) PLC存储空间的分配。虽然各种PLC的CPU的最大寻址空间各不相同,但是根

据PLC的工作原理其存储空间一般包括以下三个区域:系统程序存储区、系统RAM存储

区(包括I/O映像区和系统软设备等)、用户程序存储区。

1)系统程序存储区。在系统程序存储区中存放着相当于计算机操作系统的系统程序,

包括监控程序、管理程序、命令解释程序、功能子程序、系统诊断子程序等。由制造厂商

将其固化在EPROM中,用户不能直接存取。它和硬件一起决定了 该PLC的性能。

2)系统RAM存储区。系统RAM存储区包括I/O映像区以及各类软设备,如:逻辑

线圈、数据寄存器、计时器、计数器、变址寄存器、累加器等存储器。

CDI是能源行业工业自动化系统的领先供应商,SENSYS开发并销售用于实时数据管理的高级软件解决方案。CDI的IntelliMAX产品的最初应用将是CDI为墨西哥湾的主要海上生产设施设计和建造的液压修井装置的控制系统。CDI总裁Van Wilson说:“我们选择SENSYS的IntelliMAX是因为它的技术领先于其他人机界面。“IntelliMAX显然是为高性能和高完整性而设计的,这正是我们的石油和天然气客户所需要的。IntelliMAX附带了一整套基于OPC的接口,无需额外开发即可使用。产品的可扩展性也是我们做出决定的一个因素,因为我们的客户需要能够根据需要随时轻松扩展的系统。”SENSYS总裁Sohail Qadir表示:“虽然IntelliMAX已经在上游和下游应用中使用,但CDI的先进交钥匙解决方案为IntelliMAX提供了新的市场机遇。“我们与CDI的合作伙伴关系为我们的客户提供了获得系统集成和咨询服务的选择,以确保他们项目的成功。我们很高兴CDI成为IntelliMAX的增值经销商。”关于控制动力国际公司CD公司于1991年在德克萨斯州休斯顿成立,现已发展成为公认的行业领导者,为碳氢化合物供应链的所有环节设计和实施一些最大、最先进的控制解决方案;上游、中游和下游。CDI已经在全球完成了1000多个过程控制项目,包括分布式控制系统(DCS)、可编程逻辑控制器(PLC)和混合分布式控制系统。CDI雇佣持有电气工程、计算机科学和化学工程学位的注册专业工程师(PE)和项目管理专家(PMP)。作为ISO 9001:2000认证公司,CDI项目方法涵盖所有项目阶段,包括设计、生命周期成本分析、系统和设备选择、软件开发、质量控制程序和支持业务流程。

81001-450-53-R

81001-450-53-R A-B high voltage inverter module

I. Central Processing Unit (CPU)

The central processing unit (CPU) is the control center of the PLC. It receives and receives according to the function given by the PLC system program

Store user programs and data input from the programmer, check the status of power, memory, VO, and alert timer,

And can diagnose the syntax errors in the user program: when the PLC is put into operation, it first receives the field input by scanning

The state and data of the device are stored separately in the IO image area, and then the user program is read from the user program memory one by one

After the command interpretation, the results of logic or arithmetic operations are sent to the Vo map area or data store according to the instructions

It’s in the organ. After all the user programs are executed, the output state or output register in the 1/O image area is finally placed

The data is transmitted to the corresponding output device, and so the cycle runs until it stops running.

In order to further improve the reliability of PLCS, in recent years, dual cpus have also been used to form redundant systems for large PLCS, or

A three-CPU voting system is adopted. In this way, even if one CPU fails, the whole system can still run normally.

2. Memory

The memory that stores the system software is called the system program memory.

(1) PLC commonly used memory types.

1) RAM (Random Assess Memory). This is – a read/write memory (random access memory) with the fastest access speed, supported by the battery.

2) EPROM (Erasable Progranmable Read Only Memory). This is an erasable read-only storage

All contents of the memory remain unchanged in the case of power failure (the contents of the memory can be erased under continuous ultraviolet irradiation).

3) EPROM (Electrical Erasable Programmable Read Only Memory). This is an electrically erasable read-only memory. The contents stored in it can be easily modified using a programmer.

(2) Allocation of PLC storage space. Although the maximum addressing space of the CPU of various PLCS varies, the root

According to the working principle of PLC, its storage space generally includes the following three areas: system program storage area, system RAM storage

Area (including I/O image area and system software device, etc.), user program storage area.

1) System program storage area. In the system program store, the system program equivalent to the computer operating system is stored.

It includes monitoring program, management program, command interpreter, function subroutine, system diagnostic subroutine and so on. By the manufacturer

It is solidified in EPROM and cannot be accessed directly by the user. Together with the hardware, it determines the performance of the PLC.

2) System RAM storage area. The system RAM storage area includes the I/O image area and various software devices, such as logic

Coils, data registers, timers, counters, index registers, accumulators and other memory.

CDI is a leading provider of industrial automation systems for the energy industry, and SENSYS develops and sells advanced software solutions for real-time data management. The initial application of CDI’s IntelliMAX products will be control systems for hydraulic workover units designed and built by CDI for major offshore production facilities in the Gulf of Mexico. Van Wilson, President of CDI, said: “We chose SENSYS ‘IntelliMAX because its technology is ahead of other human-machine interfaces. “IntelliMAX is clearly designed for high performance and high integrity, which is exactly what our oil and gas customers want. IntelliMAX comes with a complete set of OPC-based interfaces that can be used without additional development. The scalability of the product was also a factor in our decision, as our customers require systems that can easily scale at any time as needed.” Sohail Qadir, President of SENSYS, said: “While IntelliMAX is already in use in upstream and downstream applications, CDI’s advanced turnkey solutions offer new market opportunities for IntelliMAX. “Our partnership with CDI gives our customers the option to access systems integration and consulting services to ensure the success of their projects.” We are pleased to have CDI as a value-added reseller for IntelliMAX.” Founded in 1991 in Houston, Texas, CD has grown to become a recognized industry leader in designing and implementing some of the largest and most advanced control solutions for all stages of the hydrocarbon supply chain. Upstream, midstream and downstream. CDI has completed more than 1,000 process control projects worldwide, including distributed control systems (DCS), programmable logic controllers (PLCS), and hybrid distributed control systems. CDI employs registered Professional Engineers (PE) and project management specialists (PMP) with degrees in electrical engineering, computer science and chemical engineering. As an ISO 9001:2000 certified company, CDI’s project approach covers all project phases including design, life cycle cost analysis, system and equipment selection, software development, quality control procedures and supporting business processes.

81001-450-53-R

| A-B | 1756-IB32 | A-B | 20-HIM-A6 | A-B | 1794-IB16 |

| A-B | 1756-IB32 | A-B | 2098-DSD-020X | A-B | 1794-ASB |

| A-B | 1769-L30ER | A-B | 1769-L33ER | A-B | 1747-L541 |

| A-B | 1762-L24BWA | A-B | 1794-AENT | A-B | 22B-D010N104 |

| A-B | 1756-OF8 | A-B | 1794-IE12 | A-B | 1756-PA72电源模块 |

| A-B | 2080-LC50-24QBB | A-B | 1794-OE12 | A-B | 1756-OF8模拟量模块 |

| A-B | 1769-L33ER | A-B | 1794-OB32P | A-B | 1756-IF16模拟量模块 |

| A-B | 1756-RM2 | A-B | 1794-IB32 | A-B | 1756-IB16数字量模块 |

| A-B | 1756-EN2TR | A-B | 1769-ECR . | A-B | 1756-EN2T通讯模块 |

| A-B | 1756-IB32 | A-B | 1769-L36ERMA | A-B | 1756-A7机架 |

| A-B | 1756-OB32 | A-B | 1756-IF16 | A-B | 1786-RPA/B |

| A-B | 1756-IF16 | A-B | 1756-IB32 | A-B | 1756-RM2 |

| A-B | 1756-OB16E | A-B | 1756-OB32 | A-B | 1756-IB32 |

| A-B | 1769-ECR | A-B | 1738-AENT SER.B | A-B | 2711P-B6C20D |

| A-B | 1756-OB16E | A-B | 1764-LSP | A-B | 1756-ENBT/A |

| A-B | 1756-TBNH | A-B | 1756-EN2T/C | A-B | 1747-L542 |

| A-B | 1756-IF16 | A-B | 1761-NET-ENI | A-B | 1770-XYC/A电池 |

| A-B | 1756-TBCH | A-B | HT-230712-1001 | A-B | 1756-BA2 |

| A-B | 1756-IB16 | A-B | SST-PFB-SLC | A-B | 1756-BA2 |

| A-B | 2711-B6C20 | A-B | 2711P-T15C4D8 | A-B | 1786-RPA |

| A-B | 1746-NI8 | A-B | 1761-L32BWA | A-B | 1771-ASB |

| A-B | 842E-CM-MIP3BA | A-B | 1761-L10BWA | A-B | 1756-IB32 |

| A-B | 1794-ACN15通讯模块 | A-B | 1756-CN2R | A-B | 1747-L514 |

There are no reviews yet.