1、数据缓冲

由于I/O设备的速率较低而CPU和内存的速率却很高,故在控制器中必须设置一缓冲器。在输出时,用此缓冲器暂存由主机高速传来的数据,然后才以I/O设备所具有的速率将缓冲器中的数据传送给I/O设备;在输入时,缓冲器则用于暂存从I/O设备送来的数据,待接收到一批数据后,再将缓冲器中的数据高速地传送给主机。

2、差错控制

设备控制器还兼管对由I/O设备传送来的数据进行差错检测。若发现传送中出现了错误,通常是将差错检测码置位,并向CPU报告,于是CPU将本次传送来的数据作废,并重新进行一次传送。这样便可保证数据输入的正确性。

3、数据交换

这是指实现CPU与控制器之间、控制器与设备之间的数据交换。对于前者,是通过数据总线,由CPU并行地把数据写入控制器,或从控制器中并行地读出数据;对于后者,是设备将数据输入到控制器,或从控制器传送给设备。为此,在控制器中须设置数据寄存器。

4、状态说明

标识和报告设备的状态控制器应记下设备的状态供CPU了解。例如,仅当该设备处于发送就绪状态时,CPU才能启动控制器从设备中读出数据。为此,在控制器中应设置一状态寄存器,用其中的每一位来反映设备的某一种状态。当CPU将该寄存器的内容读入后,便可了解该设备的状态。

5、接收和识别命令

CPU可以向控制器发送多种不同的命令,设备控制器应能接收并识别这些命令。为此,在控制器中应具有相应的控制寄存器,用来存放接收的命令和参数,并对所接收的命令进行译码。例如,磁盘控制器可以接收CPU发来的Read、Write、Format等15条不同的命令,而且有些命令还带有参数;相应地,在磁盘控制器中有多个寄存器和命令译码器等。

6、地址识别

就像内存中的每一个单元都有一个地址一样,系统中的每一个设备也都有一个地址,而设备控制器又必须能够识别它所控制的每个设备的地址。此外,为使CPU能向(或从)寄存器中写入(或读出)数据,这些寄存器都应具有唯一的地址。

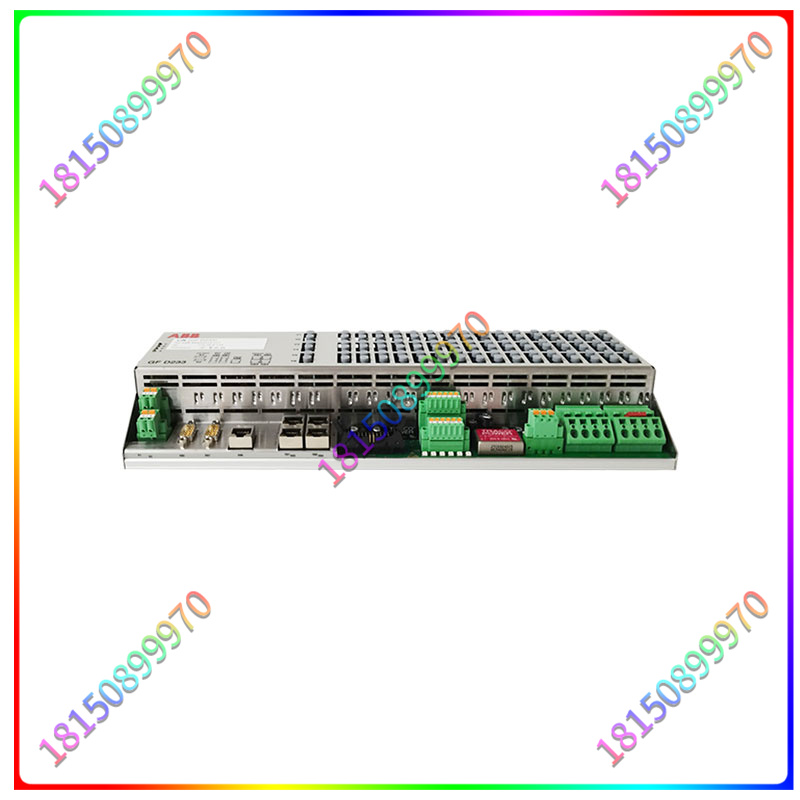

ABB GFD233A

ABB发明、制造了众多产品和技术,其中包括全球第一套三相输电系统、世界上第一台自冷式变压器、高压直流输电技术和第一台电动工业机器人,并率先将它们投入商业应用。ABB拥有广泛的产品线,包括全系列电力变压器和配电变压器,高、中、低压开关柜产品,交流和直流输配电系统,电力自动化系统,各种测量设备和传感器,实时控制和优化系统,机器人软硬件和仿真系统,高效节能的电机和传动系统,电力质量、转换和同步系统,保护电力系统安全的熔断和开关设备。这些产品已广泛应用于工业、商业、电力和公共事业中。

ABB集团位列全球500强企业(2008年在世界500强排列第256位,2009年位列第230位,2010年位列第237位),2009至2011年销售额都高达320亿美元。并在苏黎世、斯德哥尔摩和纽约证券交易所上市交易。

安全回路是保护负载或控制对象以及防止操作错误或控制失败而进行连锁控制的回路。在直接控制负载的同时,安全保护回路还给PLC输入信号,以便于PLC进行保护处理。安全回路一般考虑以下几个方面。

(1)短路保护应该在PLC外部输出回路中装上熔断器,进行短路保护。最好在每个负载的回路中都装上熔断器。

(2)互锁与联锁措施除在程序中保证电路的互锁关系,PLC外部接线中还应该采取硬件的互锁措施,以确保系统安全可靠地运行。

(3)失压保护与紧急停车措施PLC外部负载的供电线路应具有失压保护措施,当临时停电再恢复供电时,不按下“启动”按钮PLC的外部负载就不能自行启动。这种接线方法的另一个作用是,当特殊情况下需要紧急停机时,按下“急停”按钮就可以切断负载电源,同时“急停”信号输入PLC。

(4)极限保护在有些如提升机类超过限位就有可能产生危险的情况下,设置极限保护,当极限保护动作时直接切断负载电源,同时将信号输入

ABB GFD233A

1. Data buffering

Because the I/O device speed is low and the CPU and memory speed is high, a buffer must be set in the controller. When output, the buffer is used to temporarily store the data from the host at high speed, and then the data in the buffer is transmitted to the I/O device at the rate that the I/O device has; During input, the buffer is used to temporarily store the data sent from the I/O device, and after receiving a batch of data, the data in the buffer is transmitted to the host at high speed.

2. Error control

The device controller is also responsible for error detection of data transmitted by the I/O device. If an error is found in the transmission, the error detection code is usually set and reported to the CPU, so the CPU will cancel the data sent this time and retry the transmission. This ensures the correctness of data input.

3. Data exchange

This refers to the realization of data exchange between the CPU and the controller, and between the controller and the device. For the former, through the data bus, the CPU writes the data to the controller in parallel, or reads the data from the controller in parallel; In the latter case, the device inputs data to the controller, or from the controller to the device. For this purpose, a data register must be set up in the controller.

4. Status description

Identifying and reporting the status of the device The controller should record the status of the device for the CPU to understand. For example, the CPU can start the controller to read data from the device only when the device is in the send-ready state. To this end, a status register should be set up in the controller, and each bit of it reflects a certain state of the device. When the CPU reads the contents of the register, it can learn the state of the device.

5. Receive and recognize commands

The CPU can send many different commands to the controller, and the device controller should be able to receive and recognize these commands. Therefore, there should be a corresponding control register in the controller, which is used to store the received commands and parameters, and to decode the received commands. For example, the disk controller can receive 15 different commands from the CPU, such as Read, Write, Format, etc., and some commands have parameters; Accordingly, there are multiple registers and command decoders in the disk controller.

6. Address recognition

Just as every unit in memory has an address, every device in the system has an address, and the device controller must be able to recognize the address of every device it controls. In addition, in order for the CPU to write (or read) data to (or from) registers, these registers should have unique addresses.

ABB invented and manufactured many products and technologies, including the world’s first three-phase power transmission system, the world’s first self-cooling transformer, high-voltage direct current transmission technology and the first electric industrial robot, and pioneered their commercial application. ABB has a wide range of product lines, including a full range of power transformers and distribution transformers, high, medium and low voltage switchgear products, AC and DC transmission and distribution systems, power automation systems, various measuring equipment and sensors, real-time control and optimization systems, robotics hardware and software and simulation systems, energy-efficient motors and drive systems, power quality, conversion and synchronization systems, and other systems. Fusing and switching equipment to protect the safety of power systems. These products have been widely used in industry, commerce, power and public utilities.

ABB is one of the world’s top 500 companies (256th in 2008, 230th in 2009, 237th in 2010), with sales of $32 billion in 2009-2011. It is listed on the Zurich, Stockholm and New York Stock exchanges.

A safety loop is a loop of interlocking control that protects the load or control object and prevents operational errors or control failures. In the direct control of the load at the same time, the safety protection loop to the PLC input signal, in order to facilitate the PLC protection processing. Safety circuits generally consider the following aspects.

(1) Short-circuit protection should be installed in the PLC external output circuit fuse, short-circuit protection. It is best to install a fuse in the circuit of each load.

(2) Interlock and interlock measures in addition to ensuring the interlock relationship of the circuit in the program, the external wiring of the PLC should also take hardware interlock measures to ensure the safe and reliable operation of the system.

(3) Voltage loss protection and emergency shutdown measures PLC external load power supply line should have voltage loss protection measures, when the temporary power failure and then restore power supply, do not press the “start” button PLC external load can not start by itself. Another function of this wiring method is that when emergency shutdown is required under special circumstances, the load power supply can be cut off by pressing the “emergency stop” button, and the “emergency stop” signal is input to the PLC.

(4) Limit protection In some cases such as elevator class exceeding the limit may produce danger, set the limit protection, when the limit protection action directly cut off the load power supply, while the signal input PLC.

ABB GFD233A

| ABB | XVC722AE101 | ABB | PCD530A102 | ABB | LDGRB-01 |

| ABB | 3BHB002751R0101 | ABB | 3BHE041343R0102 | ABB | 3BSE013177R1 |

| ABB | 07DC92D | ABB | PPC907BE | ABB | 58052582G |

| ABB | GJR5252200R0101 | ABB | 3BHE024577R0101 | ABB | BC810K01 |

| ABB | LDGRB-01 | ABB | DAPI100 | ABB | 3BSE031154R1 |

| ABB | 3BSE013177R1 | ABB | 3AST000929R109 | ABB | CI858K01 |

| ABB | CMA130 | ABB | 3ASC25H204 | ABB | 3BSE018135R1 |

| ABB | 3DDE300410 | ABB | DAPU100 | ABB | KUC755AE105 |

| ABB | SYN5201a-Z,V217 | ABB | 3ASC25H208 | ABB | 3BHB005243R0105 |

| ABB | 3BHB006714R0217 | ABB | DATX100 | ABB | PFEA113-20 |

| ABB | 5SHY3545L0009 | ABB | 3ASC25H214 | ABB | 3BSE028144R0020-1 |

| ABB | GVC750BE101 | ABB | DATX130 | ABB | PM803F |

| ABB | 3BHE009681R0101 | ABB | 3ASC25H216A | ABB | 3BDH000530R1 |

| ABB | 3BHB013085R0001 | ABB | DATX132 | ABB | PM864AK01 |

| ABB | 3BSE050090R20 | ABB | 3ASC25H219B | ABB | 3BSE018161R1 |

| ABB | PFEA111-20 | ABB | DATX133 | ABB | 3BHE039203R0101 |

| ABB | PM864AK01 | ABB | ICSE08B5 | ABB | GVC736CE101 |

| ABB | 3BSE018161R1 | ABB | LDGRB-01 | ABB | CAI04 |

There are no reviews yet.