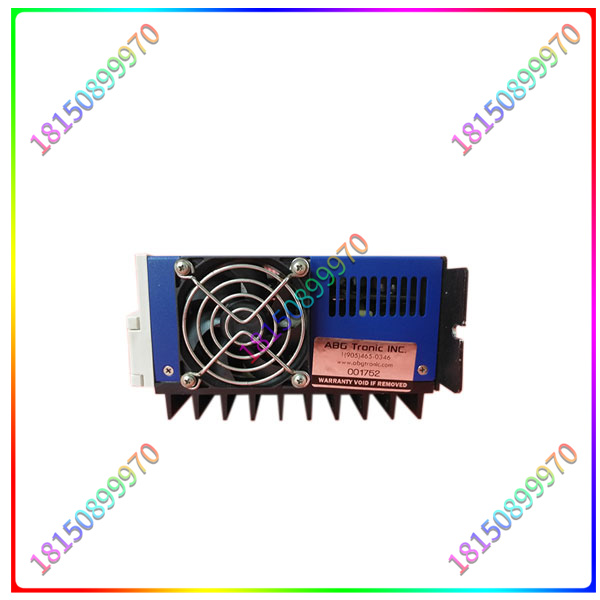

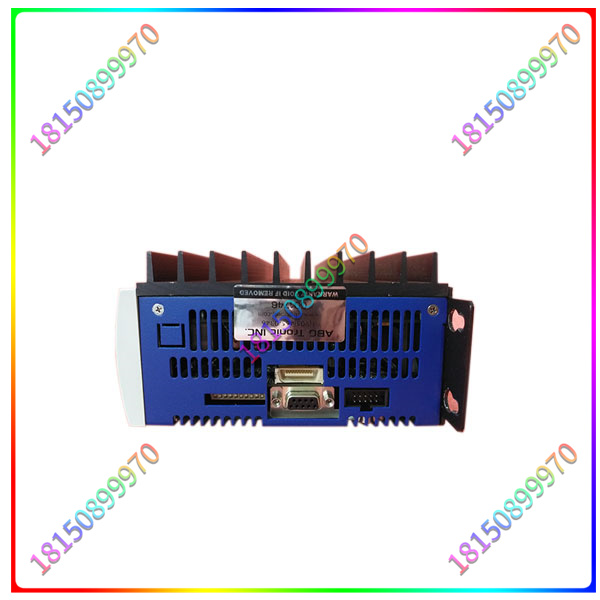

这S62000-NA数字 伺服放大器从科尔莫根连接时必须低电阻接地,以防触电。该放大器能够产生高达900伏高电压。操作过程中不得打开或触摸。未经制造商许可,不得改动该设备。它旨在用作电机和设备的组成部分。伺服放大器外壳的外导体不得超过1000伏。如果安装了放大器的机器不符合国家指令,该装置不得用于离岸应用或船舶上,也不得进行调试。这伺服放大器与一起提供保证 时期关于一个 年。

这放大器必须在-25℃和+70℃之间的温度下运输。该设备只能储存在原始的可回收包装中。它支持相位故障监控、短路保护和过压识别。该单位有两个模拟监控输出和两个可编程数字输出。本产品支持紧急停止功能,以关闭安装它的机器。必须保护数字设备免受过度压力。它必须与电源、扼流圈和滤波器尽可能靠近地安装在机柜内的接地导电安装板上。

CB06551/CB06561/CB06560伺服放大器可能由于错误或不合适的电机接线以及错误的电源电压而损坏。可编程逻辑控制器监控设备的状态,以确认紧急情况。可以使用修改产品的设置安装软件。控制电缆和电源电缆必须分开布线,相互之间的距离至少为200毫米。用于连接的电缆必须符合EN 60204要求。在敦豪、联邦快递等合作公司的帮助下,我们可以将数字放大器运送到世界上的任何地址。

CB06551

CB06551 PRD-B040SSIB-63与作为绝对位置反馈设备的解析器相反,编码器是指示位置变化的增量设备。SERVOSTAR®的编码器分辨率(因此驱动器的编码器等效输出)是固定的,因为它是编码器设备的硬件特性。编码器接口包括三组导线:

1。A/B(和补码)线:这些线组成编码器的正交信号。在通过断线检测电路之前,通过线路接收器差分地接收信号。

2.指数脉冲:这种窄脉冲通常每转出现一次,表示轴的已知物理位置。该脉冲在通过断线检测电路之前通过线路接收器被差分地接收。此信号可通过硬件捕获。

3霍尔信号:这些信号提供了表示电机轴大致绝对位置的信息。根据这些信息,电机可以正弦换向,直到检测到索引信号,此时才知道真实位置。这些信号由光耦合器隔离,可以是差分信号或开放式信号。

CB06551

This S62000-NA digital servo amplifier must be grounded with low resistance when connected from Kormogan to prevent electric shock. The amplifier is capable of producing high voltages up to 900 volts. Do not open or touch during operation. The equipment shall not be altered without the permission of the manufacturer. It is intended to be used as a component of motors and equipment. The outer conductor of the servo amplifier housing shall not exceed 1000 volts. If the machine with the amplifier installed does not comply with the national directive, the device shall not be used in offshore applications or on ships, nor shall it be commissioned. This servo amplifier comes with a guaranteed period about one year.

This amplifier must be transported at temperatures between -25 ° C and +70 ° C. The device can only be stored in its original recyclable packaging. It supports phase fault monitoring, short circuit protection and overvoltage identification. The unit has two analog monitoring outputs and two programmable digital outputs. This product supports an emergency stop function to shut down the machine on which it is installed. Digital devices must be protected from excessive stress. It must be mounted as close as possible to the power supply, choke and filter on a grounded conductive mounting plate in the cabinet.

The CB06551/CB06561/CB06560 servo amplifier can be damaged due to incorrect or inappropriate motor wiring and wrong supply voltage. The programmable logic controller monitors the status of the device to confirm emergency situations. You can install the software using Settings that modify the product. The control cable and the power cable must be routed separately and at least 200 mm away from each other. The cables used for connection must comply with EN 60204. With the help of partner companies such as DHL and fedex, we can ship digital amplifiers to any address in the world.

CB06551 PRD-B040SSIB-63 In contrast to a parser that acts as an absolute position feedback device, the encoder is an incremental device that indicates a change in position. The encoder resolution of SERVOSTAR® (and therefore the encoder equivalent output of the driver) is fixed because it is a hardware feature of the encoder device. The encoder interface consists of three sets of wires:

1. A/B (and complement) lines: These lines make up the orthogonal signal of the encoder. The signal is received differentially through the line receiver before passing through the line break detection circuit.

2. Exponential pulse: This narrow pulse usually occurs once per revolution and indicates the known physical position of the shaft. The pulse is received differentially by the line receiver before passing through the break detection circuit. This signal can be captured by hardware.

3 Hall signals: These signals provide information indicating the approximate absolute position of the motor shaft. Based on this information, the motor can be sinusoidal commutation, until the index signal is detected, at which time the true position is not known. These signals are isolated by optical couplers and can be differential or open signals.

CB06551

| ABB | 07DC92D | ABB | PPC907BE | ABB | 58052582G |

| ABB | GJR5252200R0101 | ABB | 3BHE024577R0101 | ABB | BC810K01 |

| ABB | LDGRB-01 | ABB | DAPI100 | ABB | 3BSE031154R1 |

| ABB | 3BSE013177R1 | ABB | 3AST000929R109 | ABB | CI858K01 |

| ABB | CMA130 | ABB | 3ASC25H204 | ABB | 3BSE018135R1 |

| ABB | 3DDE300410 | ABB | DAPU100 | ABB | KUC755AE105 |

| ABB | SYN5201a-Z,V217 | ABB | 3ASC25H208 | ABB | 3BHB005243R0105 |

| ABB | 3BHB006714R0217 | ABB | DATX100 | ABB | PFEA113-20 |

| ABB | 5SHY3545L0009 | ABB | 3ASC25H214 | ABB | 3BSE028144R0020-1 |

| ABB | GVC750BE101 | ABB | DATX130 | ABB | PM803F |

| ABB | 3BHE009681R0101 | ABB | 3ASC25H216A | ABB | 3BDH000530R1 |

| ABB | 3BHB013085R0001 | ABB | DATX132 | ABB | PM864AK01 |

| ABB | 3BSE050090R20 | ABB | 3ASC25H219B | ABB | 3BSE018161R1 |

| ABB | PFEA111-20 | ABB | DATX133 | ABB | 3BHE039203R0101 |

| ABB | PM864AK01 | ABB | ICSE08B5 | ABB | GVC736CE101 |

| ABB | 3BSE018161R1 | ABB | LDGRB-01 | ABB | CAI04 |

| ABB | UFC762AE101 | ABB | 3BSE013177R1 | ABB | CI871K01 |

| ABB | 3BHE006412R0101 | ABB | LDGRB-01 | ABB | 3BSE056767R1 |

| ABB | 1HSB495663-2 | ABB | 3BSE013177R1 | ABB | CP405 |

| ABB | 1MRS050644 | ABB | PP865A | ABB | A0 |

| ABB | 1MRS050729 | ABB | 3BSE042236R2 | ABB | 1SAP500405R0001 |

| ABB | 1SAJ924007R0001 | ABB | PPD512A10-150000 | ABB | DI04 |

| ABB | PCD235B1101 | ABB | UFC760BE41 | ABB | DO810 |

There are no reviews yet.