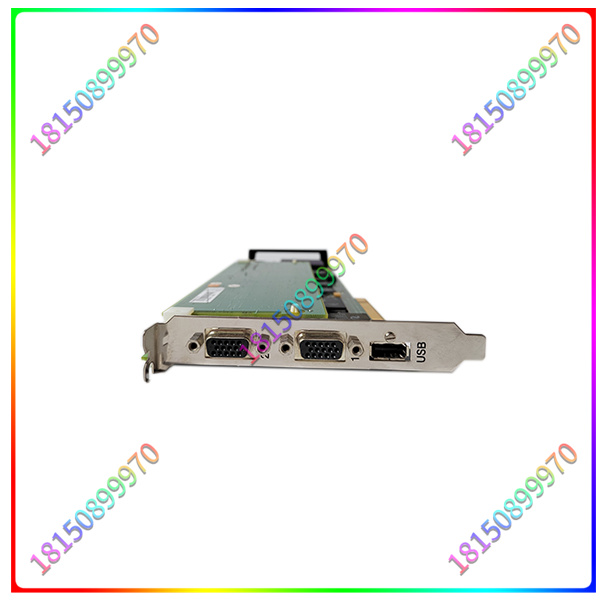

PU519输入/输出卡传感器、按钮、开关、继电器、螺线管甚至网络设备与连接到 I/O 卡上的螺丝端子的 I/O 信号共享信息。可以根据每台机器和设施的需要选择这些卡。在一些小型 PLC中,I/O 端子不是模块化卡,而是方便地安装在 PLC 的侧面。由于 I/O 设备结构种类繁多,分立和模拟模块的种类繁多,模拟模型的术语有“源”与“灌”,“电压”与“电流” 。编程设备和人机界面PLC 本身之外有两个非常重要的组件:PU519编程设备和人机界面 (HMI)。编程设备可以是来自同一制造商的台式计算机、膝上型计算机或手持式仪器。一些小型 PLC 甚至在前面有按钮,可以在不需要计算机的情况下对非常基本的逻辑操作进行编程。

PU519

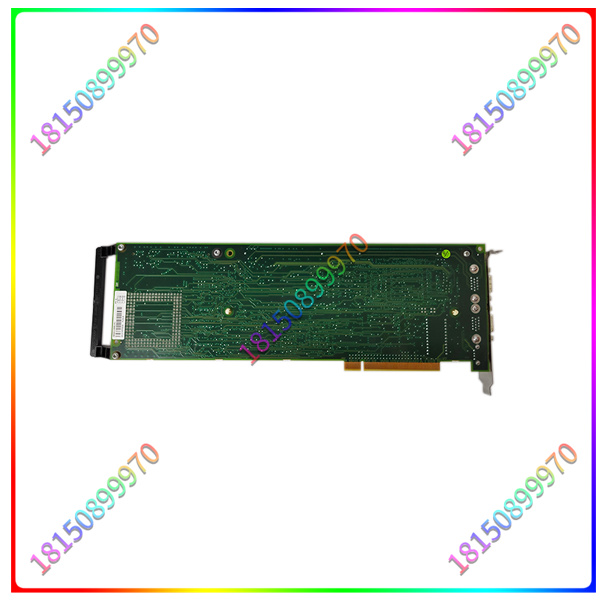

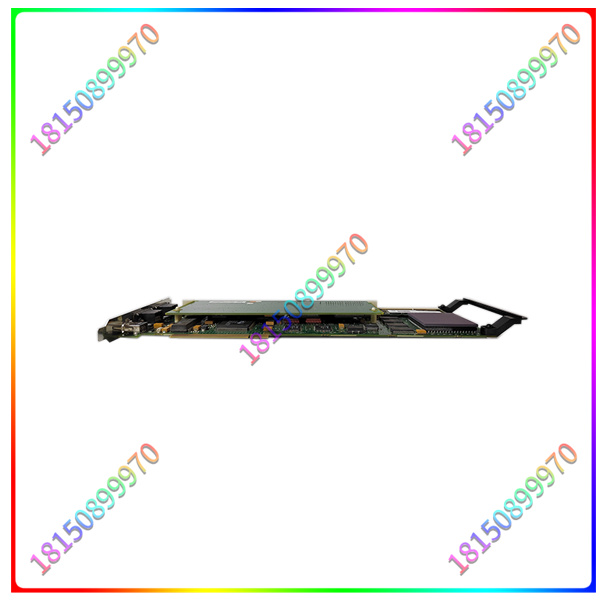

PU519基本组件PLC由几个基本部分组成。它们可能看起来与各个制造商略有不同,但每个组件的用途和范围是相同的。PU519其中包括电源、中央处理单元 (CPU)、输入/输出卡以及放置输入/输出 (I/O) 卡的背板或机架。如图 2 所示,背板在所有独立组件之间建立了电气连接,从而为 PLC 提供了模块化设计。这种电连接包括电源和通信信号。PU519许多 PLC 制造商在背板上使用专有通信协议,以便 I/O 可以安全地与 CPU 通信。电源根据应用和安装环境,电源可接受 120VAC 或 24VDC。如上所述,此电压通过背板为 CPU 和 I/O 模块提供电源,这些模块以“卡”的形式出现。这些卡可以从它们在载体中的插槽中快速添加或移除。需要注意的是,CPU 的电源并不为传感器和线圈等现场设备供电。此电源连接必须单独与卡建立。

PU519

PU519 Input/output card sensors, buttons, switches, relays, solenos, and even network devices share information with the I/O signals connected to the screw terminals on the I/O card. These cards can be selected according to the needs of each machine and device. In some small PLCS, the I/O terminals are not modular cards, but are conveniently mounted on the side of the PLC. Due to the wide variety of I/O device structures and the wide variety of discrete and analog modules, the terms of the simulation model are “source” and “perfusion”, “voltage” and “current”. There are two very important components outside the PLC itself: the PU519 programming device and the Human Machine Interface (HMI). The programming device can be a desktop computer, laptop, or handheld instrument from the same manufacturer. Some small PLCS even have buttons on the front that allow very basic logic operations to be programmed without the need for a computer.

PU519 Basic components A PLC consists of several basic components. They may look slightly different from individual manufacturers, but the purpose and scope of each component is the same. The PU519 includes a power supply, a central processing unit (CPU), an input/output card, and a backplane or rack for the input/output (I/O) card. As shown in Figure 2, the backplane establishes electrical connections between all the individual components, thus providing a modular design for the PLC. This electrical connection includes a power supply and a communication signal. Many PLC manufacturers use proprietary communication protocols on the backplane so that I/O can securely communicate with the CPU. Power Supply Depending on the application and installation environment, the power supply can accept either 120VAC or 24VDC. As mentioned above, this voltage supplies power to the CPU and I/O modules through the backplane, which come in the form of “cards.” These cards can be quickly added or removed from their slots in the carrier. It should be noted that the CPU’s power supply does not power field devices such as sensors and coils. This power connection must be established separately from the card.

PU519

| ABB | 3BHE019719R0101 | ABB | PM864AK01 | ABB | 4899001-NK |

| ABB | GVC736BE101 | ABB | 3BSE018161R1 | ABB | IBA |

| ABB | 5SHY4045L0003 | ABB | PM902F | ABB | 940143201 |

| ABB | 3BHB021400 | ABB | 3BDH001000R0005 | ABB | IDPG |

| ABB | 3BHE019719R0101 | ABB | PPC907BE | ABB | 940128102 |

| ABB | GVC736BE101 | ABB | 3BHE024577R0101 | ABB | LC-608 |

| ABB | CS5133BSE000435R1 | ABB | REM620A_F | ABB | LDGRB-01 |

| ABB | KUC711AE101 | ABB | NAMBBABA33E5BNN1XF | ABB | 3BSE013177R1 |

| ABB | 3BHB004661R0101 | ABB | XO08R2 | ABB | LXN1604-6 |

| ABB | MB810 | ABB | 1SBP260109R1001 | ABB | NDCU-12C |

| ABB | PCD235B101 | ABB | 5SHY3545L0010 | ABB | NDCU-12CK |

| ABB | 3BHE032025R0101 | ABB | 5SHY3545L0010 | ABB | OCAH |

| ABB | PFEA111-20 | ABB | 3BHB013088R0001 | ABB | 940181103 |

| ABB | 3BSE050090R20 | ABB | 3BHE009681R0101 | ABB | OCAHG |

There are no reviews yet.